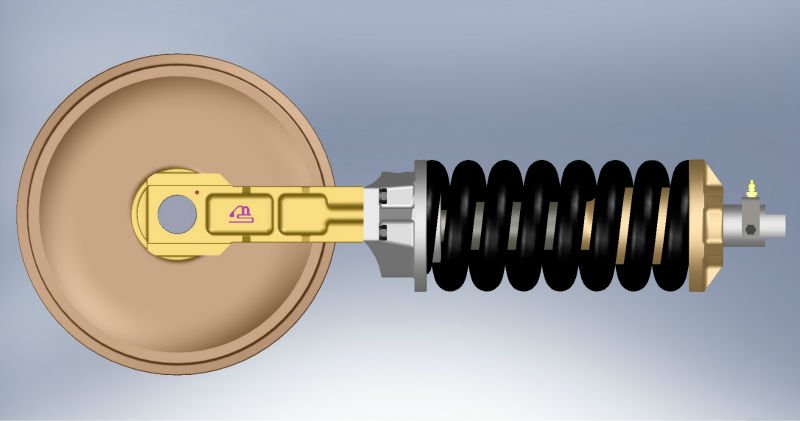

The undercarriage is heavy equipment such as a crawler Excavator Track Tensioner, which includes many moving components that need to be maintained carefully to avail of the good performance. The undercarriage is not maintained and inspected properly; it will end up spending on too much money for the components repair. Also, it will potentially decrease the track’s life span. Thus, it is necessary to maintain it carefully to keep in good condition in order to improve the performance. If you want to know the things to maintain that, then continue to read.

Keep The Undercarriage Clean

This is essential that is important to follow at the end of each workday, Excavator Track Tensioner, takes time to clean out complete dirt but you should do that to avoid some risk factors. The shovels and pressure washers can be used to clean the dirt easily. If you failed to do clean, it will accelerate premature wear on components and it will happen especially in a colder climate. It is because the dirt and debris will freeze in a cold condition and it will start to rub on the bolts. If it happens that will loosen the guiding and seize up a roller which leads to potential wear later on. It is because regular cleaning is necessary to maintain them in good condition.

Routine Inspect The Undercarriage

This is another important factor that you need to follow to keep the undercarriage in good condition. According to the research, if the machine is used to harder applications or challenging conditions, the undercarriage is needed to inspect frequently. All the components are important to inspect without any restrictions such as drive motor, drive sprockets, rock guards, track bolts, track chains, and more.

These are the main things that you need to follow in order to maintain your Excavator Track Tensioner.